Silage crop losses will occur if poor or incorrect procedures are used. The following guidelines

may help to pinpoint any potential problems:

POOR QUALITY CROP

- Crop not of optimum quality for cutting.

- Grass contaminated by soil due to mower setting too low.

- Extended wilting period allowing quality of crop to deteriorate.

- Poorly shaped bales, with ‘shoulders’, allowing air to become trapped during wrapping.

The use of a net, which can guarantee full width bale coverage, will avoid this.

FILM LAYERS OPENING

- Low cling properties of the film used.

- Insufficient layers of film applied.

- Crop, netwrap or twine protruding between layers preventing a good seal.

- Uneven film overlap on bale. This can be caused by:

- Incorrectly calibrated wrapper.

- Insufficient number of turns of the bale (minimum 16 turns for 750mm – 24 turns for 500mm – on a 1.2 x 1.2m bale, for 4-layer coverage.

For 6 layer coverage – turn bale 24 turns on 750mm filmand 36 turns for 500mm film.)

- Oversized, or misshapen bales (where the greater circumference of the bale will require extra turns to ensure the correct overlap of film).

- Film over-stretches – often caused by over-tacked pre-stretch rollers.

FILM SPLITTING

Damaged film used during wrapping, causing it to tear when stretched

- Insufficient film applied

Most often found in the area of the bale ahead of the last film applied, signifying the need for another turn of the bale during wrapping.

Also, remember the first half turn of the bale is required to bring the film up to its full width on application to the bale.

- Film Over-Stretch

Often caused by poorer quality film in higher ambient temperatures, excessive turntable speeds when wrapping or over-tacked

pre-stretch rollers causing an increase in film ‘neck-down’, leading to reduced film over-lap.

- Bird damage

Usually very easy to identify, holes through all layers with crop pulled up through the film. Mostly, these holes are found on bale tops only,

though can occur at ground level when bales are left in the field after wrapping. This can be avoided by using Novatex Silage Nets, raffia style netting on a roll.

- Punctured film

Often caused by wrapping crop with very high dry matter (DM), or when bales are ejected from turntable directly onto dry grass stubble.

For best results, always wrap in the same area of the field, to allow all bales to fall onto same smooth area on the floor.

FILM BREAKS WHEN WRAPPING

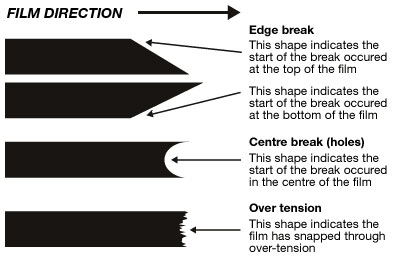

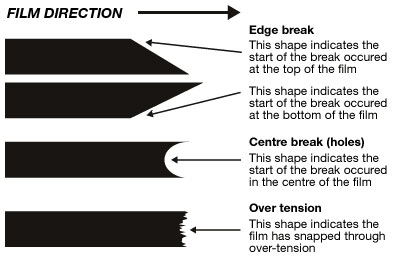

If film breaks when wrapping, a close examination of the film break profile will help to identify where the break began. From this, the cause of the break can often be traced back to either the roll, the bale or the film catching on the wrapper, depending where the break began.

The diagram below ilustrates this: